As environmental consciousness grows, the demand for sustainable building materials that offer both functionality and eco-friendliness has never been more significant.

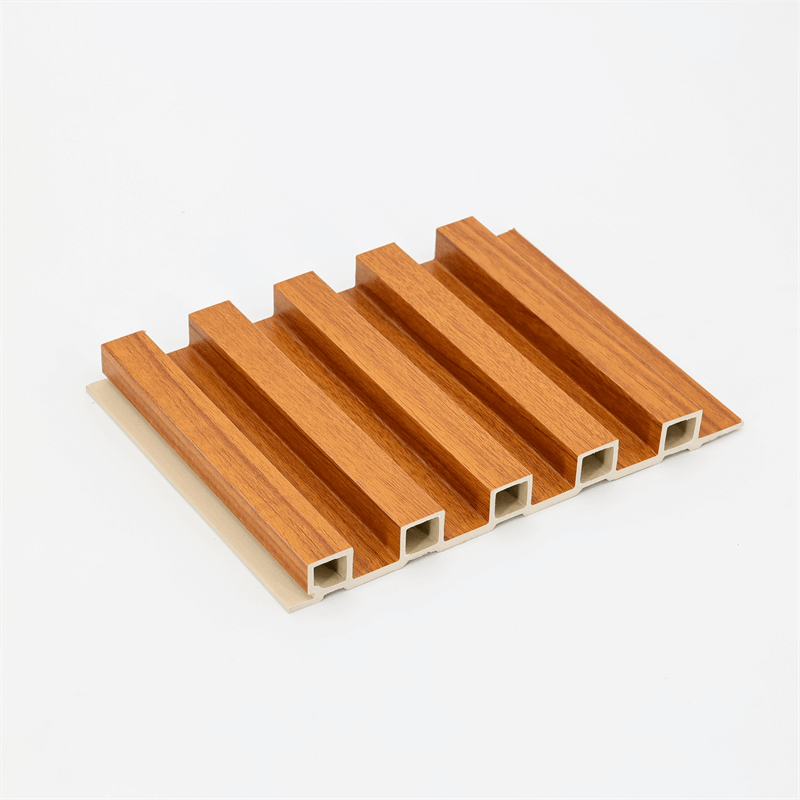

Wood Plastic Composite (WPC) wall panels have emerged as a remarkable solution that checks both boxes.

These panels combine the natural appeal of wood with the durability of plastic, providing a versatile and waterproof building material.

In this article, we explore the environmental benefits of WPC wall panels, from their use of recycled materials to their water-resistant properties,

making them a compelling choice for eco-conscious consumers and architects alike.

Repurposing Waste: The Eco-Friendly Nature of WPC Wall Panels

Utilizing Recycled Wood Fibers

One of the key environmental benefits of WPC wall panels lies in the use of recycled wood fibers as the primary component.

These fibers are derived from a variety of sources, such as sawdust, wood chips, and wood shavings, which would otherwise end up in landfills or contribute to deforestation.

By repurposing waste wood, WPC panels minimize the strain on natural resources and reduce the environmental impact of the construction industry.

Sustainable Forestry Practices

In addition to utilizing recycled wood fibers, some WPC manufacturers source their materials from sustainable forestry practices.

This means that the wood used in the panels comes from responsibly managed forests, where trees are harvested in a manner that supports the regeneration and conservation of the forest ecosystem.

Choosing WPC wall panels made from sustainably sourced materials further enhances their eco-friendliness.

Reducing Plastic Waste: The Role of WPC Wall Panels

Minimizing Single-Use Plastic

Plastic waste has become a global environmental concern, with single-use plastics being a significant contributor.

By incorporating plastic waste into the production of WPC wall panels, the building industry can contribute to reducing the amount of single-use plastic that ends up in landfills or pollutes our oceans.

This sustainable approach to plastic usage aligns with the principles of a circular economy, where materials are reused, recycled, and repurposed to minimize waste generation.

Extended Product Lifespan

One of the significant advantages of WPC wall panels is their extended product lifespan.

Compared to traditional wood or non-waterproof materials, WPC panels are more resistant to decay, moisture, and damage.

The durability of these panels means that they require less frequent replacement, reducing the overall demand for new materials and extending the life cycle of building components.

Energy-Efficient Manufacturing of WPC Wall Panels

Reduced Energy Consumption

The manufacturing process of WPC wall panels is designed to be energy-efficient.

By using extrusion and compression molding techniques, the production of WPC panels consumes less energy compared to other energy-intensive processes used for conventional building materials.

The reduction in energy consumption during manufacturing contributes to a lower carbon footprint and a more sustainable building material.

Closed-Loop Production Systems

Some WPC manufacturers adopt closed-loop production systems, which aim to minimize waste and conserve resources during the manufacturing process.

In closed-loop systems, waste materials generated during production are recycled and reintegrated into the manufacturing process, reducing the need for new raw materials and minimizing waste generation.

Water-Resistant Design: Promoting Sustainable Building Practices

Preventing Water Damage and Waste

Water damage to buildings can be costly both economically and environmentally.

WPC wall panels’ water-resistant properties serve as a preventive measure against moisture-related issues such as mold, mildew, and rot, reducing the need for extensive repairs or replacements.

By using WPC panels as a waterproof solution, the construction industry can contribute to sustainable building practices that prioritize durability and resource conservation.

Long-Lasting and Low-Maintenance

The water-resistant nature of WPC wall panels translates into a long-lasting and low-maintenance building material.

Their resistance to moisture and decay means that they require minimal treatments and coatings to protect them from water damage.

As a result, less maintenance is needed over the life of the panels, reducing the consumption of resources and minimizing waste generated from maintenance activities.

Wood Plastic Composite (WPC) wall panels represent a sustainable and waterproof building material that offers numerous environmental benefits.

By utilizing recycled wood fibers and repurposing plastic waste, WPC panels contribute to reducing the strain on natural resources and minimizing plastic pollution.

Their long product lifespan, energy-efficient manufacturing process, and closed-loop production systems further enhance their eco-friendliness.

Moreover, the water-resistant properties of WPC wall panels promote sustainable building practices by preventing water damage and reducing the need for resource-intensive maintenance.

As the construction industry strives towards sustainable and responsible building practices,

WPC wall panels continue to emerge as an environmentally conscious choice that combines durability, functionality, and aesthetics in harmony with the planet.