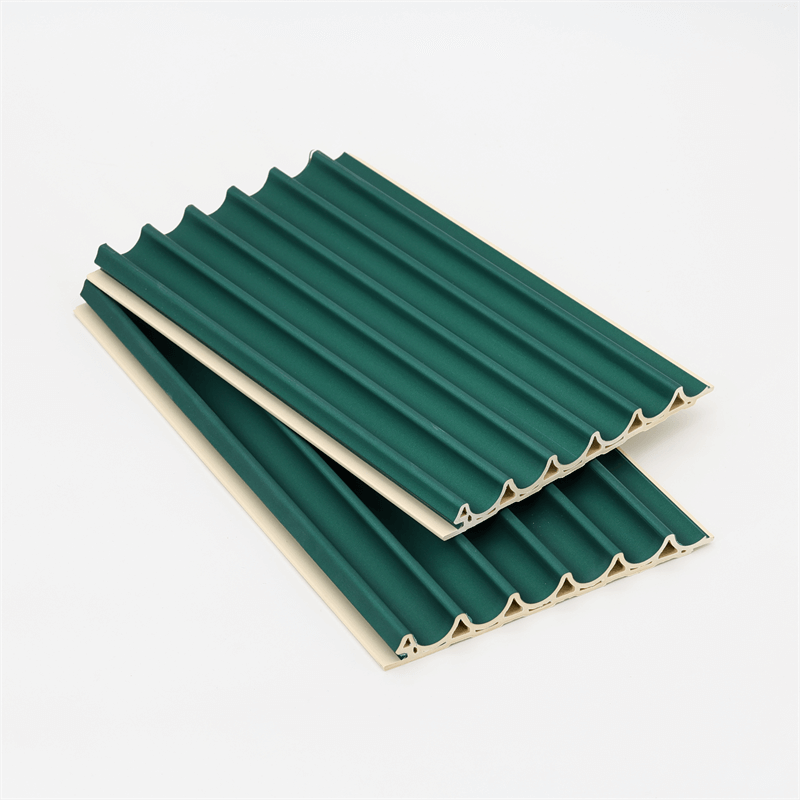

Wood Plastic Composite (WPC) wall panels have gained significant popularity in the construction and design industry due to their exceptional waterproofing properties and aesthetic appeal.

When installing WPC wall panels, proper techniques are essential to ensure effective waterproofing and prolong the panels’ lifespan.

This step-by-step guide aims to provide comprehensive instructions for the installation process, from surface preparation to final touches.

By following these guidelines, you can ensure that your WPC wall panels remain protected and maintain their stylish appearance for years to come.

Preparing the Surface for WPC Wall Panel Installation

Before installing WPC wall panels, thorough surface preparation is crucial to achieve optimal waterproofing and ensure a seamless installation process.

Clean and Level the Surface

Begin by thoroughly cleaning the surface where the WPC panels will be installed.

Remove any dirt, debris, or previous coatings to ensure a clean and smooth foundation for the panels.

It is essential to level the surface to avoid uneven panel placement, which could lead to gaps that may compromise the waterproofing.

Apply a Moisture Barrier

To enhance the waterproofing of the WPC wall panels, consider applying a moisture barrier on the surface before installation.

A high-quality waterproof membrane or sealant creates an additional protective layer between the wall and the panels, preventing moisture from seeping through and causing damage over time.

Ensure the moisture barrier is evenly applied and fully adheres to the surface.

Installing the WPC Wall Panels

Proper installation of the WPC wall panels is crucial to achieving effective waterproofing and ensuring a secure and aesthetically pleasing result.

Choose the Right Fastening Method

The method of fastening WPC wall panels depends on the type of panels and the specific design requirements.

Common fastening options include screws, nails, or clips. Make sure to use fasteners designed for outdoor use to withstand environmental conditions and avoid corrosion.

Interlock or Tongue-and-Groove Design

Many WPC wall panels come with an interlocking or tongue-and-groove design that allows for seamless and secure connections between panels.

Ensure that the interlocking edges or grooves are correctly aligned during installation to maintain a tight fit and minimize the risk of water infiltration.

Leave Expansion Gaps

WPC panels, like any other building material, can expand or contract due to changes in temperature and humidity.

To accommodate these movements and prevent buckling or warping, leave small expansion gaps between the panels and adjacent structures.

These gaps should be evenly spaced along the perimeter and covered with appropriate moldings for a neat finish.

Ensuring Proper Sealants and Caulking

Sealants and caulking play a crucial role in effective waterproofing for WPC wall panels, as they seal gaps and joints, preventing water from penetrating through.

High-Quality Sealants and Caulks

Choose high-quality sealants and caulks specifically designed for outdoor and waterproofing applications.

Silicone-based sealants are often recommended for their excellent water resistance and flexibility, which allows them to adapt to the panel movements without compromising the seal.

Seal Joints and Connections

Apply the sealant or caulk generously to seal all joints and connections between the WPC wall panels.

Pay special attention to corners, edges, and areas where panels meet other surfaces, such as windows or doors.

A well-sealed installation will prevent water from infiltrating these vulnerable points, maintaining the panels’ waterproofing integrity.

Post-Installation Maintenance and Inspection

After installing the WPC wall panels, regular maintenance and inspection are essential to identify and address any issues that may compromise the waterproofing.

Regular Cleaning and Inspection

Establish a routine for cleaning the WPC wall panels, removing any dirt or debris that may accumulate over time.

Regular inspections should be carried out to identify signs of water damage, discoloration, or gaps in the sealants.

Address any issues promptly to prevent further water infiltration and maintain the panels’ aesthetics and performance.

Reapplying Sealants as Needed

Over time, sealants and caulks may deteriorate due to exposure to weather elements.

As part of routine maintenance, inspect the sealants and reapply as needed to ensure that the joints and connections remain properly sealed.

This proactive approach will help prolong the effectiveness of the waterproofing and prevent potential water-related issues.

Proper installation techniques and attention to detail are crucial for ensuring effective waterproofing for WPC wall panels.

By following the step-by-step guidelines outlined in this article, you can create a robust and reliable waterproof barrier for your walls.

Beginning with surface preparation and moisture barrier application, proceeding with secure and aligned panel installation,

and concluding with thorough sealing and caulking, each step plays a vital role in achieving long-lasting and stylish results.

Regular maintenance and inspections post-installation will help identify any issues early on and address them promptly,

ensuring that your WPC wall panels remain protected and visually appealing for many years to come.