Innovations in the construction industry have led to the development of advanced building materials,

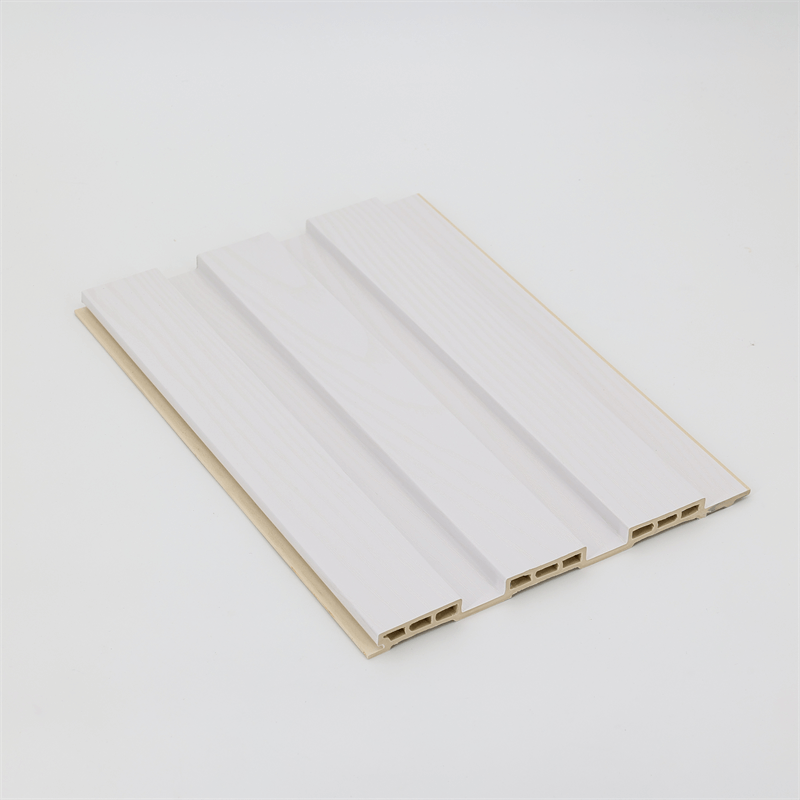

and Wood Plastic Composite (WPC) wall panels stand out as a prime example.

These panels offer a unique combination of natural aesthetics and enhanced durability, making them an excellent choice for various interior and exterior applications.

One of the key features that make WPC wall panels highly sought-after is their exceptional waterproof technology.

In this article, we delve into the science behind WPC wall panel waterproofing, uncovering the composition,

manufacturing processes, and additives that contribute to their impressive water-resistant properties.

Understanding the Composition of WPC Wall Panels

Wood Fibers: The Natural Foundation

At the core of WPC wall panels lies wood fibers, which serve as the primary natural component.

These wood fibers are obtained from a variety of sources, including hardwood and softwood waste.

The use of recycled wood makes WPC panels an eco-friendly option that promotes sustainable building practices.

Thermoplastics: Enhancing Strength and Water Resistance

To impart strength and water resistance to WPC wall panels, thermoplastics are introduced into the composition.

Commonly used thermoplastics include polyethylene, polypropylene, and polyvinyl chloride (PVC).

The addition of these plastics reinforces the structure of the panels, allowing them to withstand environmental stresses, including moisture exposure.

Additives: Fine-Tuning the Properties

In addition to wood fibers and thermoplastics, various additives are incorporated into the WPC wall panel formula.

These additives serve several purposes, such as improving bonding between wood and plastic, enhancing UV resistance, and increasing fire-retardant properties.

Additives play a crucial role in fine-tuning the physical and chemical characteristics of the panels, ensuring they meet specific performance requirements.

The Manufacturing Process of WPC Wall Panels

Extrusion: Merging Wood and Plastic

The manufacturing process of WPC wall panels begins with an extrusion method.

In this process, wood fibers and thermoplastics are blended together under controlled temperature and pressure conditions.

The mixture is heated and then extruded into the desired shape, such as long planks or panels.

During extrusion, the wood fibers and thermoplastics form a homogenous matrix, creating a sturdy and durable material.

Compression Molding: Achieving Precise Profiles

To produce intricate designs or detailed surface textures on WPC wall panels, compression molding is employed.

This process involves placing the extruded material into a mold and applying high pressure and heat to shape it precisely according to the desired profile.

Compression molding allows manufacturers to create panels with various textures and finishes, providing endless design possibilities for consumers.

Waterproofing Agents and Technologies in WPC Wall Panels

Hydrophobic Additives: Repelling Water Molecules

The exceptional waterproofing of WPC wall panels is achieved through the incorporation of hydrophobic additives.

These additives have a natural aversion to water, causing water molecules to bead up on the surface of the panels rather than being absorbed.

As a result, the panels remain impervious to moisture, preventing water-related issues such as swelling, warping, or rotting.

Protective Coatings: Enhancing Water Resistance

To further enhance the waterproofing capabilities of WPC wall panels, manufacturers may apply protective coatings on the surface.

These coatings act as an additional barrier against water infiltration, ensuring that the panels remain resilient even in harsh weather conditions.

UV-resistant coatings are also commonly used to safeguard the panels from fading or discoloration due to sun exposure.

Advantages of WPC Wall Panel Waterproof Technology

Durability and Longevity

The incorporation of hydrophobic additives and protective coatings in WPC wall panels makes them highly durable and long-lasting.

Their resistance to water damage and decay ensures that they maintain their structural integrity and appearance over time, even in challenging environments.

Minimal Maintenance

WPC wall panels’ waterproof technology significantly reduces the need for extensive maintenance.

Unlike traditional wood, WPC panels do not require regular staining, sealing, or painting to protect them from moisture.

Routine cleaning with mild soap and water is typically sufficient to keep the panels looking pristine.

Versatility in Applications

WPC wall panels’ waterproof properties make them suitable for a wide range of applications, both indoors and outdoors.

From bathrooms and kitchens to exterior facades and decking, these panels offer a versatile solution that combines practicality with aesthetic appeal.

Wood Plastic Composite (WPC) wall panels have revolutionized the construction industry, thanks to their exceptional waterproof technology.

By blending wood fibers, thermoplastics, and various additives during the manufacturing process, WPC panels achieve an ideal balance of natural aesthetics and enhanced durability.

The incorporation of hydrophobic additives and protective coatings ensures that WPC wall panels repel water, making them an excellent choice for interior and exterior applications.

With their durability, minimal maintenance requirements, and design versatility, WPC wall panels offer a sustainable and stylish solution for modern building projects.

As technology continues to advance, WPC wall panels are likely to remain at the forefront of innovative building materials, providing effective waterproofing for a multitude of spaces.